Did you know? More than half of RÖHM's clamping and gripping technology consists of customized solutions for customers from a wide range of technology sectors. Our engineers put all their know-how into the development of these solutions. RÖHM products are known to be among the best in their class. Robustness, precision and intelligent force and motion control – these are also the hallmarks of our customer-specific solutions.

Do you have a special clamping task? Put us to the test!

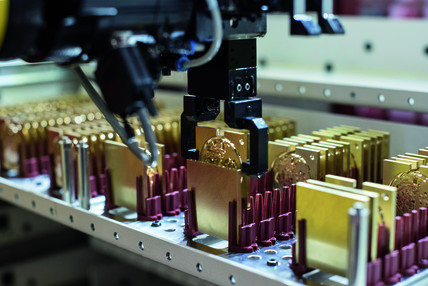

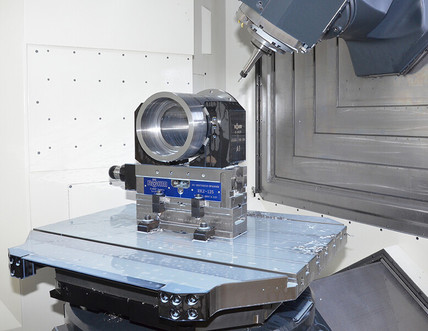

High-tech clamping solution for watch plates

IWC Schaffhausen relies on the compact 5-axis machining center KERN Micro for the reliable and repeatable production of watch plates. Mounted on it is the award-winning power clamping swivel chuck from RÖHM from the Micro Technology series. This enables double-sided blank machining without reclamping. This enables IWC to achieve maximum precision and repeat accuracy in a single clamping operation with dozens of machining steps and numerous tool changes.

Workpiece: Watch blanks

Task: Reliable and repeatable clamping for the repeatable and double-sided machining of watch plates

Solution: Power clamping swivel chuck KPF-MT

Customer benefits: Maximum precision and reduced set-up times thanks to double-sided blank machining in a single clamping operation

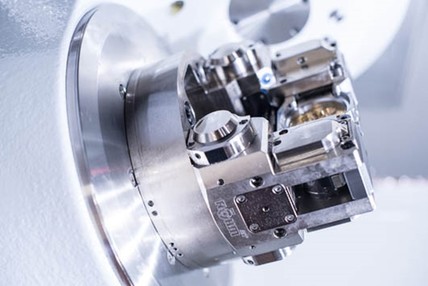

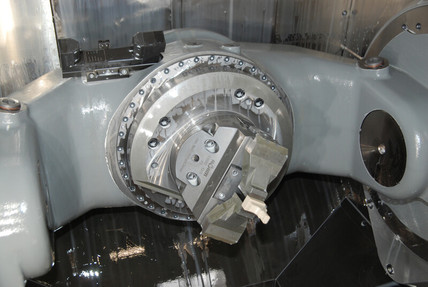

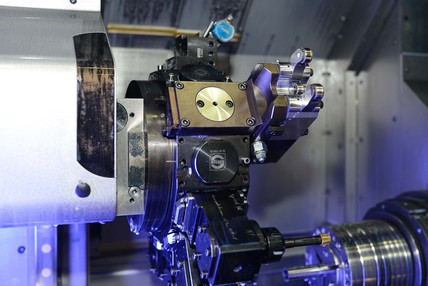

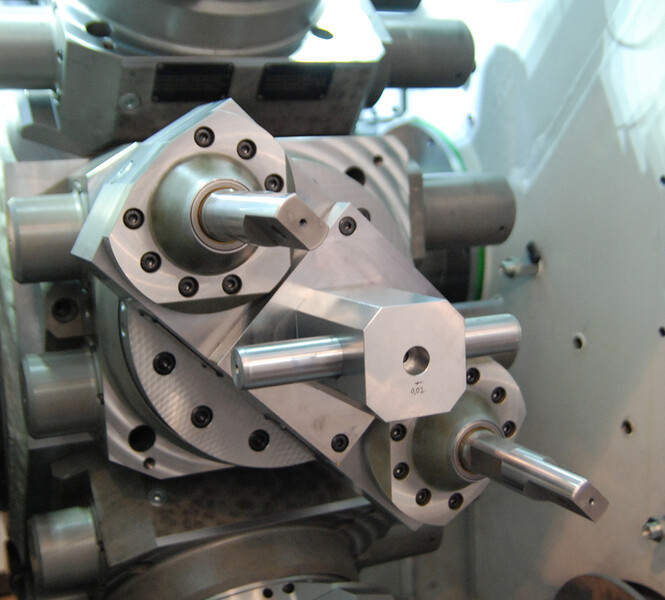

AUTOMATED MACHINING OF UNIVERSAL JOINTS ON ROTARY TRANSFER MACHINES

FFG Werke GmbH in Offenburg succeeded in landing an order from a Chinese company in 2015. The company is called Wanxiang and is one of the largest automotive suppliers in China. The component, of which Wanxiang produces around 60 million units per year, is the universal joint of a cardan drive in three different sizes. Witzig & Frank developed an eight-station rotary transfer machine of the LSA type for this purpose. As machining was to be carried out from four sides, an interesting clamping concept was developed in collaboration with RÖHM.

Workpiece: Universal joint of a cardan drive

Task

Fully automated four-sided complete machining of universal joints on an eight-station rotary transfer machine from Witzig& Frank

Solution

An intelligent clamping device integrated into the machine concept, which not only has the 'open and close' function, but also a kind of virtual W-axis that rotates exactly 90 degrees.

Customer benefit

The intelligent clamping device integrated into the machine concept had a positive effect on the 'part to part' cycle times and the compact design of the machine.

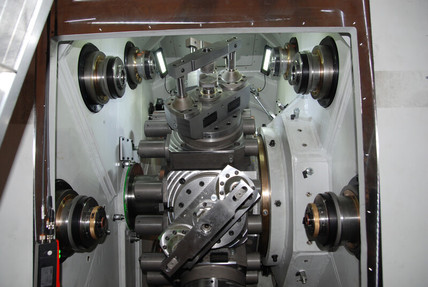

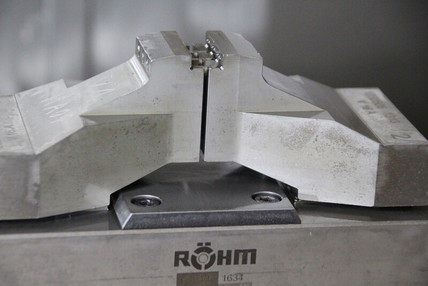

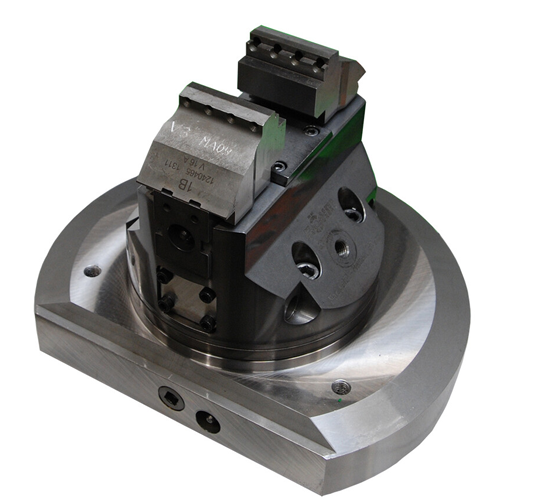

PROCESSING OF A WIDE RANGE OF PARTS WITH STATIONARY CLAMPING VICE SSP

In close cooperation with a global customer base, EVG develops innovative systems for the production of micro and nano components. The product range includes lithography systems, wafer bonding systems and inspection systems. The vice from RÖHM with quick-change jaws and V-profile jaws has a jaw stroke of 30 mm, making it ideal for the wide range of parts produced by EVG.

Workpiece: Vice workpieces

Task

Processing of a wide range of parts with external dimensions from 20x20 mm to 200x200 mm

Solution

Stationary vice SSP with quick jaw change and V-profile jaws

Customer benefit

Only 8 clamping devices instead of 37 are required for the wide range of parts. This not only saves space and costs, but also reduces maintenance costs.

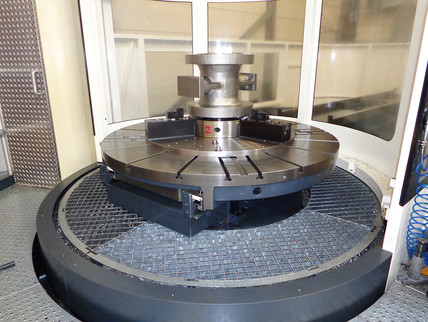

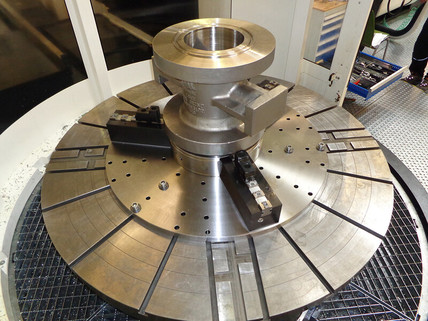

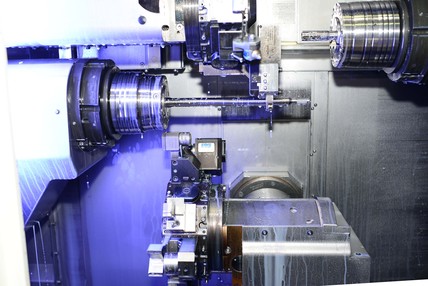

Manufacturing cast and VA housings with RÖHM manual chuck DURO-TA XT

On request, cast and stainless steel housings are produced with great reliability, from the initial idea through development to completion, predominantly in individual production. NTG has invested in a state-of-the-art turn-mill center from DMG for their production. NTG has opted for a DURO-TA XT manual chuck from RÖHM so that the DMC 210 FD can perform as flexibly as possible.

Workpiece: Cast and VA housings

Task

Machining large and small workpieces with frequent changes

Solution

3-jaw manual chuck with quick-change system DURO-TA XT 1200 mm

Customer benefit

Possibility to change from large to small workpieces in just minutes. High clamping force and radial run-out accuracy, low deadweight - and all of this with a diameter of 1200 mm

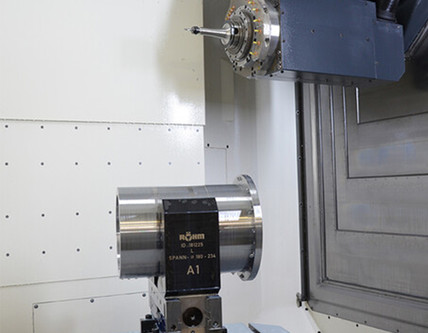

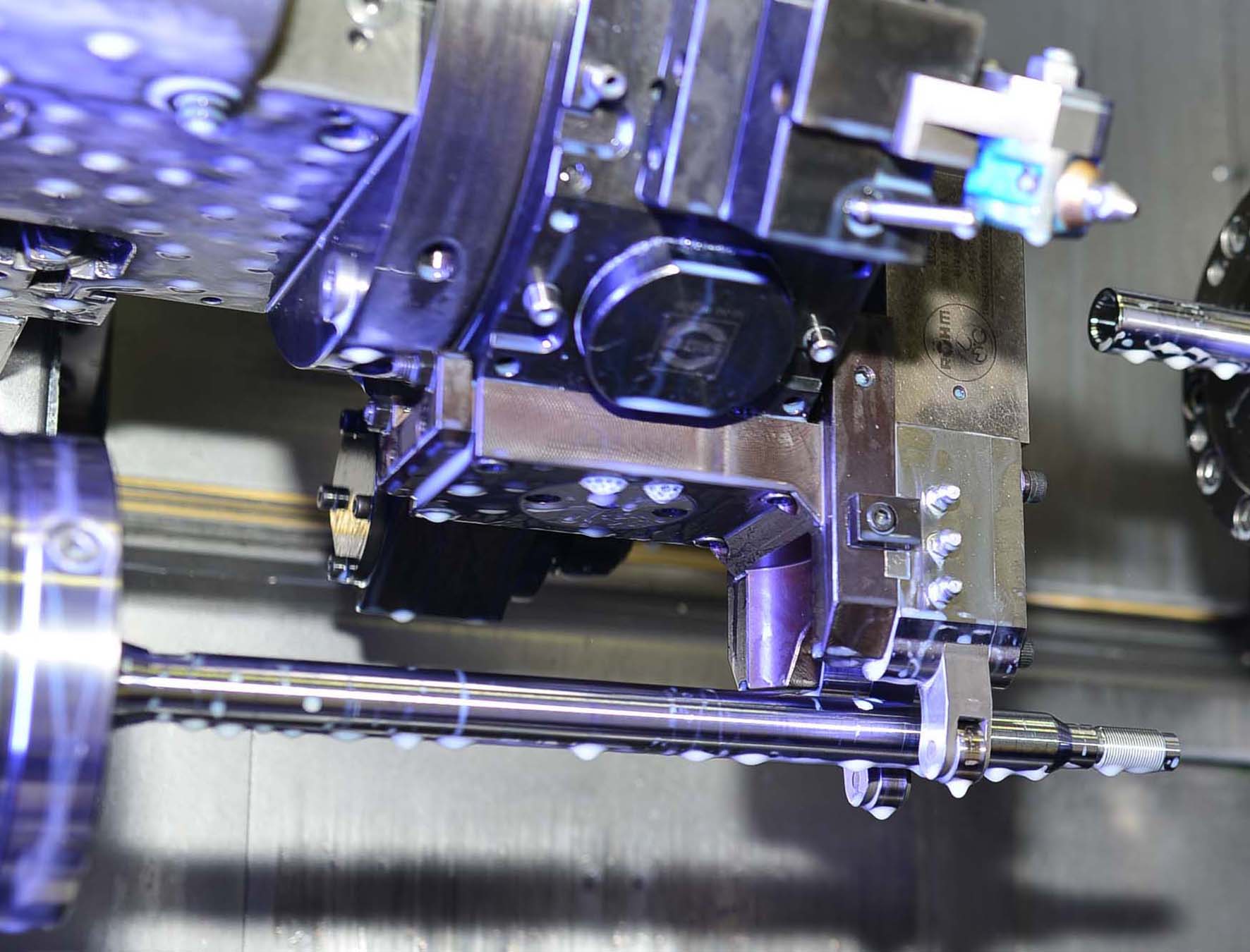

Machining of spindles with NC-Compact self centering vice RKZ

GMN Paul Müller Industrie GmbH manufactures spindles for machine tools as custom manufacturing at the highest level. To do justice to this claim in its own manufacturing in Nuremberg as well, the manufacturing specialists rely on the long-lasting and precision clamping devices from Röhm.

Workpiece: Metal mandrel catridges

Task

Clamping of mandrel catridges for milling processing

Solution

RÖHM NC-Compact self centering vice RKZ with customized jaws

Customer benefit

Because of the 3-sided machining, manufacturing of parts with just one clamping process is now possible.

Turret steady rest easily retrofitted - the coolant pressure gives the control command

Wesa GmbH in Waldstetten specializes in CNC complete machining and uses an extensive range of machinery - from prototype construction to series production - mainly for automotive manufacturers and suppliers. A workpiece support was required for the DMG Sprint 50 CNC lathe, on which mainly long, thin components are manufactured, in order to be able to machine them with high precision.

Workpiece: Part of the rear-wheel steering of sports cars

Task

Workpiece support for CNC lathe with design specifications: small tool turret, limited working space, no hydraulic connection, defined clamping range between 18 - 36 mm

Solution

RÖHM turret mounted, coolant operated steady rest

Customer benefit

Successful retrofitting of the CNC lathe without installing an additional medium