We see the past and future as being inseparable

The company has enjoyed a very lively history. From the very beginning, our self-image has always involved important values such as quality, customer proximity and innovation as well as an awareness of our responsibility and tradition. As such, the eventful history of RÖHM is particularly one of a courageous and forward-looking founding family of entrepreneurs, which has always been committed to the future.

Innovation, technology, precision and quality

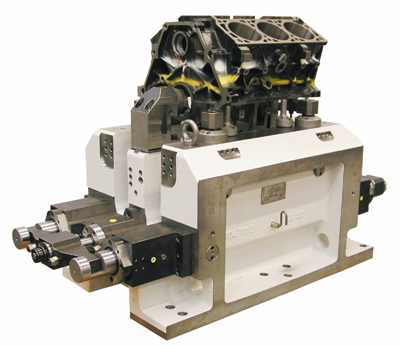

Today, around 1000 employees manufacture first-class clamping technology from the smallest drill chucks up to high-tech power clamping equipment. RÖHM is one of the most important clamping technology specialists worldwide, and with about 50 subsidiaries and representatives, it is always very close to the customer.

Here, RÖHM consistently observes the top topics of Industry 4.0, i.e. lightweight construction, energy efficiency and additive manufacturing. In all solutions, our customers profit from fast processes for ordering and service, and they can rely on being able to use the product in manufacturing within the shortest possible time.

Takeover by Rothenberger Holding

On 18 September 2017, the RÖHM Group will be represented by Dr. Ing. Helmut Rothenberger Holding GmbH from Salzburg. Within the Rothenberger Group, RÖHM meets the requirements of Industry 4.0 with regard to energy-saving and networked clamping and gripping systems for machine tools and the robot industry.

Expansion of the European market

With the establishment of branches in Poland and Hungary, RÖHM is further expanding its network in the European market. In each case the new head office is opened in the USA and Mexico.

RÖHM eShop and new grinding centre

RÖHM presents the first eShop in the clamping technology industry and thereby proves its innovative competence not only for products.

By purchasing the Kehren RP 8-2 vertical grinding centre in a portal design, components of power chucks and devices can be machined with diameters of up to 1200 mm, heights of up to 1000 mm and weights of up to 2000 kg.

Expansion der RÖHM Group in weitere Länder

With the establishment of subsidiaries in Singapore and Mexico RÖHM expanding its international presence. With its competent partners, the company is always on the spot, according to the motto "In the market - for the market".

Global Player in the field of clamping technology

Today, around 1,500 employees produce top quality clamping tools - from the smallest drill chuck to the most high-tech power-assisted clamping device. This makes RÖHM one of the most important international providers and with more than 60 establishments and agents its always close to its customers.

Commissioning of the automated warehouse for small parts at the headquarter

By the means of the 55 m long and 12 m high automated warehouse for small parts with its 11,000 bin locations, RÖHM will satisfy the trend towards ever shorter life cycles and tight target deadlines. Sale of the arms division to UMAREX. The RÖHM Group therefore concentrates on its core competencies.

Change in the management

After 99 years at the helm, the management of the RÖHM family business was passed to the external Managing Director Dr.-Ing. Michael Fried. By doing this, the Röhm family implemented the decision which was adopted by the partners in 2007 in order to withdraw from the operative side of the business. The family still jointly decides on the fortunes of the established business as shareholders and members of the advisory board.

New production hall at the site in Dillingen / Expansion of the global orientation

Construction of a 1650 square meter production hall at the site in Dillingen, in which two portal turning and milling machines are commissioned in 2008 which are specially adapted to RÖHM's requirements. The machines are constructed for the processing of workpieces of up to four meters in diameter and up to 25 tons in weight, with a machine net weight of 108 tons. Therefore a special foundament of 180 tons of iron and steel was build. Establishment of RÖHM Slovakia Establishment of RÖHM India Establishment of the Joint Venture RÖHM WEIDA Machinery China The new manufacturing bases in Slovakia and India as well as the Joint Venture in China are the latest steps that the company has taken in order to be better, faster and more efficient. At the same time, the developments represent the clear international orientation of the group.

New production hall at the headquarter

Completion of the 8570 square meter production hall at the headquarter in Sontheim. The new halll combines turning, milling and grinding shop, inspection area with measuring machines as well as assembly of all articles outside the product division of drill chucks.

RÖHM global

The consequent internationalization with the development of distribution and service establishments went hand in hand with the additional orientation towards the sector of special applications, one of the company's greatest strengths.

RÖHM Spain

Establishment of the RÖHM Iberica S.A. in Spain.

RÖHM St. Georgen

Establishment of RÖHM´s branch at St. Georgen. The St. Georgen site is a small, yet acomplished high-tech forge. In addition to standard clamping mandrels, this is where tailor-made solutions are developed for a wide range of different requirements.

RÖHM S.A.R.L. France

Establishment of the RÖHM branch RÖHM S.A.R.L. in France.

ROHM Products of USA

Establishment of the RÖHM Tool in the United States of America. The change into the ROHM Products of America (RPA) took place in 1990.

RÖHM Italia S.R.L.

Establishment of the RÖHM branch RÖHM Italia S.R.L.

RÖHM Spanntechnik AG (Switzerland)

Establishment of the present RÖHM Spanntechnik AG (Switzerland), as a general representative.

RÖHM Great Britain / ROHM do Brasil

Establishment of the RÖHM Great Britain Ltd, at this time as a General representative. The change into the RÖHM GB Ltd took place in 1977. Establishment of the present ROHM IND. E COM. DE FERRAMENTAS DE FIXACAO LTDA in Sao Paulo (Brazil). In 1978 the site was expanded by a new production hall.

The branch factory in Dillingen/Danube

With the foundation of the branch factory in Dillingen/Danube, it was possible to meet the constant increase in demand for products Made by RÖHM. In the mid-1950s, there was a trend towards power-operated systems. RÖHM therefore invested into the field of power chuck technology and allowed further growth.

Relocation to Sontheim/Brenz

In 1946 they were relocated to Sontheim/Brenz. Without capital and without a plot of land, the company was set up again from scratch. First of all, childrens' toys were made from plywood and wood waste in a leased carpentry. With the production of rock drills, a change was quickly made again to the business of metal machining. In autumn, a barrack was constructed on the newly purchased land - the basis for today's RÖHM factories.

RÖHM grows continuously

The two operations in Ohrdruf and Warnsdorf were bought and incorporated into the company.

In addition, a 40 m conveyor belt for the production of drill chucks was put into service. With 1,500 employees, this makes RÖHM the most modern and strongest provider in the sector.

First production of key-type drill chucks

During this year, RÖHM started the production of key-type drill chucks; the first company in Germany to do so. To satisfy the needs of the market, high performance drill chucks, lathe chucks, quick change chucks and pressure reading patented live centres round off the range.

Expansion of the production plants

Business developed well, both home and abroad. With the construction of the company's own hardening shop, the production facility was expanded further.

The year of the company´s foundation

Heinrich Röhm founded the company in Zella-Mehlis, Thuringia. First of all, two-jaw drill chucks were produced. In the following year, 1910, the first patent was filed; improved drill chucks.