您的夹紧技术已初具规模——RÖHM为客户量身定制解决方案

您知道吗?RÖHM的夹紧和抓持技术系列产品中,超过半数是由为不同技术领域客户量身定做的解决方案组成的。我们的工程师将全部心血付诸于这些解决方案的研发中。RÖHM产品在同类中出类拔萃——坚固、精密且具备对力与运动的智能化控制功能。这些特质在标准产品和客户定制产品中均有同样的体现。

个性化夹紧方案的专家

RÖHM始终重点关注您的生产流程优化。缩短装配时间在其中扮演了决定性角色。让我们向您展示我们的解决方案如何助您缩短装配时间并降低零件成本!

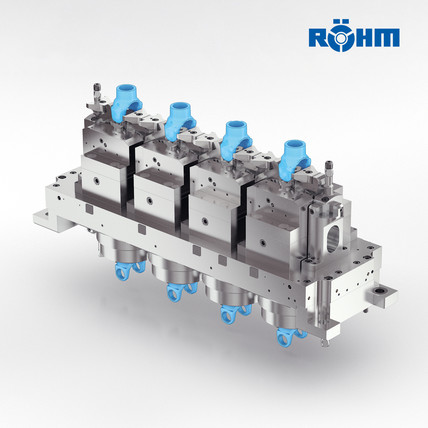

特定应用场景下的多重夹紧常常是提高效率的关键!我们的个性化四重、六重乃至八重夹紧技术无需改装便能够加工多个工件。这样可以显著提升生产力——这恰恰是我们的目的所在。凭借我们在工程和生产方面的专长,我们研发和生产为客户量身定制的夹紧装置,可以从容应对几乎任何复杂的夹紧需求。

丰富多样的解决方案亦能在您的行业中大放异彩

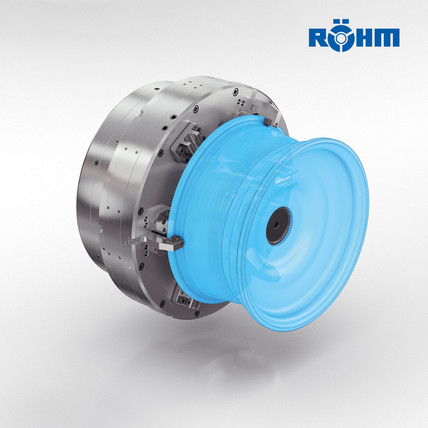

无论是油气业中用于大型套筒离心力补偿的翻转卡盘、带有虎钳的四重夹紧塔还是带有定心补偿的六爪卡盘——我们针对特定应用场景的解决方案总能应对得宜。我们的解决方案多种多样,正如我们的客户来自各行各业。在过去的25年中,仅在汽车工业领域,我们便研发了1,000多种个性化解决方案。机械、设备和机床制造方面的解决方案更是不胜枚举。

高标准严要求

RÖHM对自己的要求是明确的:即便是生产中最不寻常的工件夹紧和抓持解决方案也必须成为现实。我们的技术能够夹紧和抓持任何工件,无论形状多么复杂、表面多么敏感。所有技术完美融入每一个生产流程和每一台加工机械中——无论是手动还是全自动。

您有特殊的夹紧需求?我们乐意迎接一切挑战!

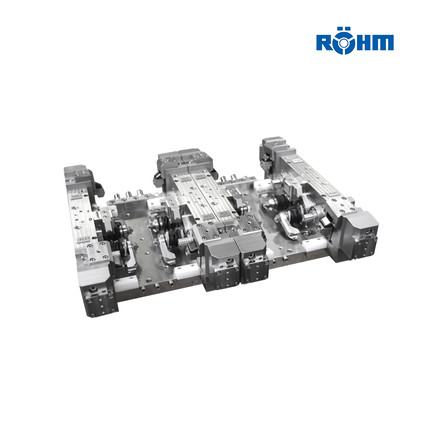

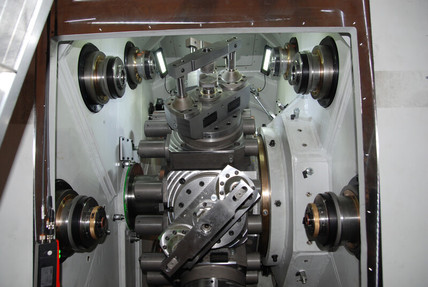

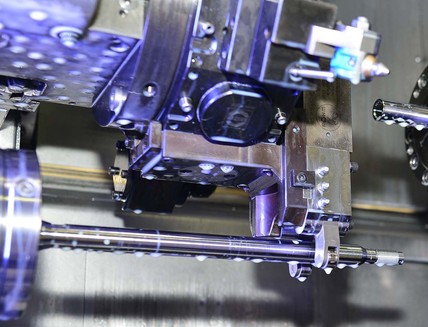

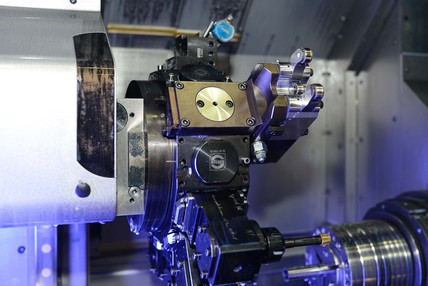

在旋转传送机上自动加工万向节

友嘉实业集团有限责任公司(FFG Werke GmbH)奥芬堡分公司于2015年成功获得了一家中国公司的订单。这家中国公司叫做万向集团,是中国最大的汽车零部件供应商之一。万向集团每年生产约6000万件万向传动装置的万向节,有三种尺寸。为此,维茨希•弗兰克(Witzig & Frank)公司开发了LSA型八站式旋转传送机。由于加工需要从四个侧面进行,故而与RÖHM公司合作开发了一种有趣的夹紧设计。

工件: 万向传动装置的万向节

任务: 在维茨希•弗兰克(Witzig & Frank)公司的八站式旋转传送机上对万向节进行全自动四面完整加工

解决方案: 集成到机床设计中的智能夹紧装置,不仅具有“开合”功能,还具有能精确旋转90度的虚拟W轴。

优势: 集成到机床设计中的智能夹紧装置对“零件到零件”的循环时间和机床的空间紧凑设计产生了积极的影响。

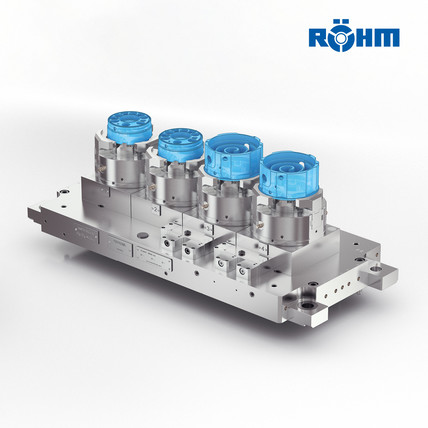

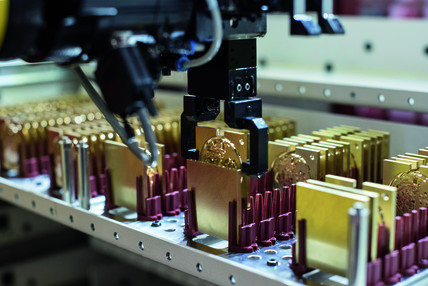

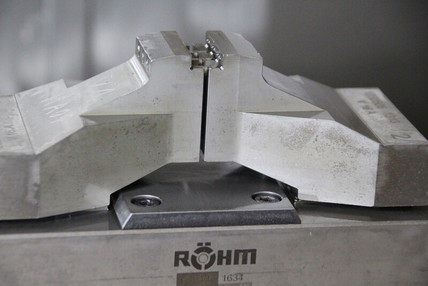

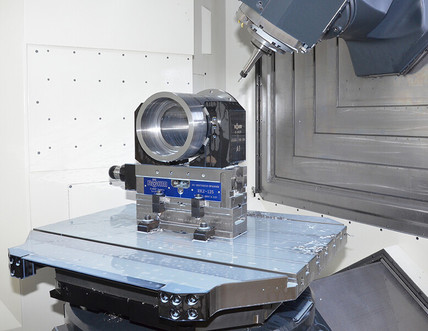

使用固定式SSP虎钳加工多种多样的零件

EVG公司与全球客户紧密合作,研发用于生产微米级乃至纳米级部件的创新设备。产品范围包括光刻设备、晶圆键合设备和检测系统。带有卡爪快速更换系统和V形钳口的RÖHM虎钳钳口行程较大,可达30 mm,因而让EVG公司在生产丰富多样的零件时如虎添翼。

工件: 虎钳工件

任务: 加工丰富多样的零件,尺寸从20x20 mm至200x200 mm不等

解决方案: 带有卡爪快速更换系统和V形钳口的SSP固定式虎钳

优势: 只需8个夹紧装置即可生产出变种多样的零件,而非37个。这样不仅节约了空间和成本,还降低了维保工作量。

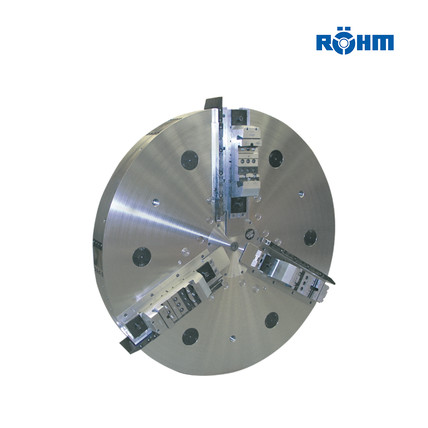

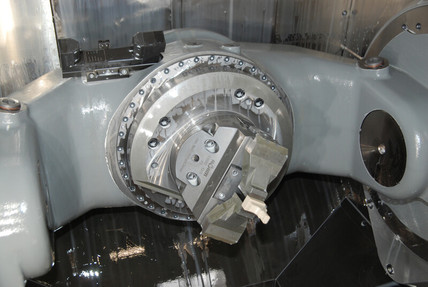

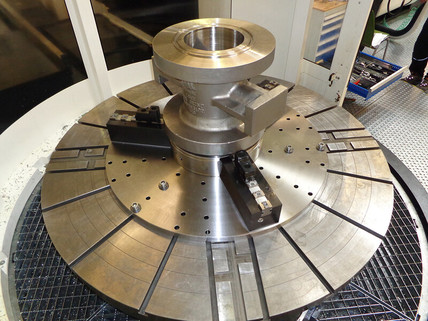

使用RÖHM楔形杆卡盘DURO-TA XT生产铸铁和不锈钢外壳

铸铁和不锈钢外壳可靠耐用,从构思到研发再到生产均可实现量身定做,通常都是少量生产。为了生产出这些外壳,NTG公司投资了一台最先进的DMG车削铣削加工中心。为了DMC 210 FD加工中心能够充分灵活发挥自身性能,NTG公司决定采用RÖHM的手动卡盘DURO-TA XT。

工件: 铸铁和不锈钢外壳

任务: 在频繁更换中加工大小不等的工件

解决方案: 带有卡爪快速更换系统的三爪式1200 mm手动卡盘DURO-TA XT

优势: 只需几分钟即可从大工件切换为小工件。夹紧力大、同心度高、重量轻——加工直径达1,200 mm时同样游刃有余。

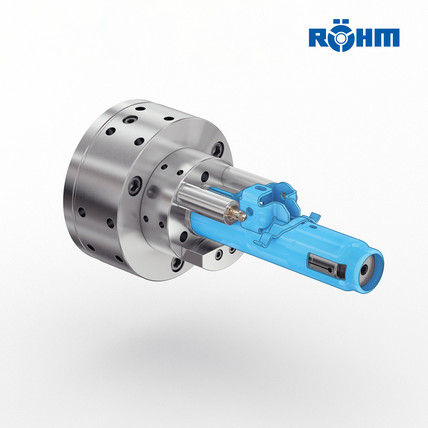

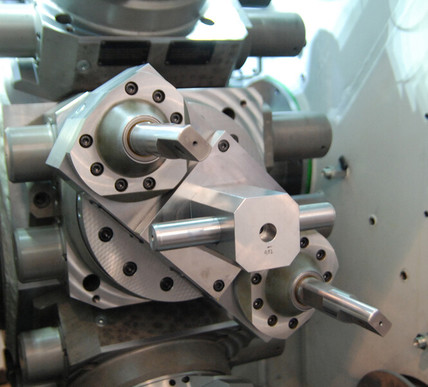

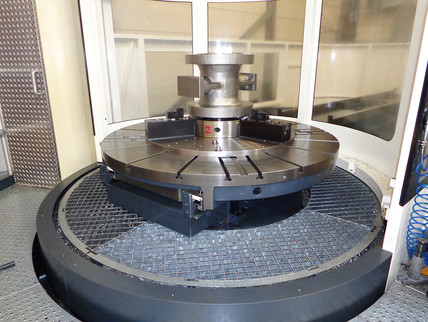

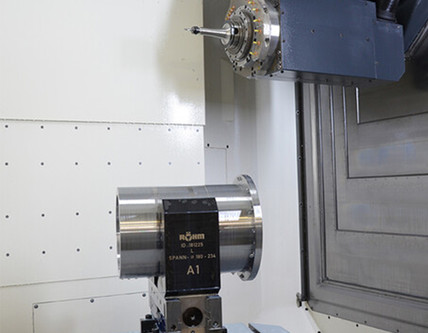

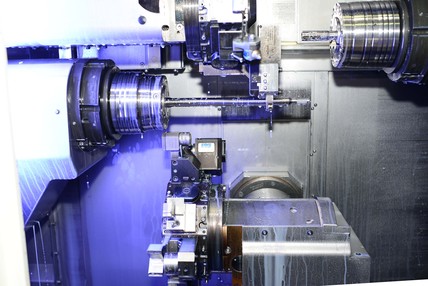

使用RKZ数控紧凑型定心夹具加工主轴套筒

GMN公司(GMN Paul Müller Industrie GmbH)生产顶尖水平的机床主轴定制产品。为了在位于纽伦堡的自家生产线上同样落实这一要求,生产专家们采用了带有特殊卡爪的RÖHM标准数控紧凑型定心夹具RKZ。

工件: 金属主轴套筒

任务: 夹紧主轴套筒,以完成铣削加工

解决方案: 带有特殊卡爪的RÖHM数控紧凑型定心夹具

优势: 借助该夹具能够实现三面加工,一次夹紧便能生产出所需零件。