Hardly any milling or drilling operations without a vise. Accordingly, there are many different types. In any case, there are vises at RÖHM that hold your workpiece with a high clamping force. That is the basic requirement for precision machining and hence results with quality.

5-axis clamp RVM, off-centre clamping

High-precision manual workpiece vise with high clamping force of up to 80 kN and very good accessibility.

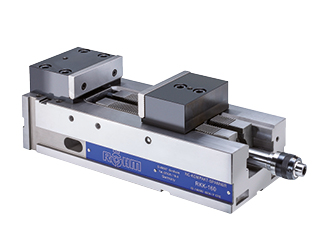

NC-Compact vises

RKE series for the highest clamping precision up to 60 kN, with fixed jaw clamping

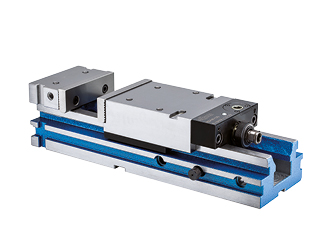

NC-Compact vises, precision design

for the highest precision and clamping precision up to 60 kN, with fixed jaw clamping

NC-Compact centering vises

for the highest clamping precision up to 25 kN, centric clamping

NC-Compact twin vises

for simultaneous clamping of two workpieces with up to 40 kN, centric clamping

5-axis centering vise

for very large clamping strokes and best accessibility up to 25 kN, centric clamping

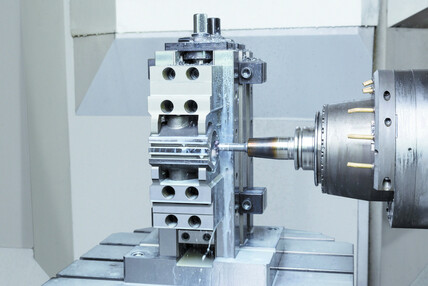

NC power vises

for 6-sided machining in two setups on multi-axis machines up to 55 kN and strokes up to 18 mm

Grinding and inspection vises

for maximum clamping precision

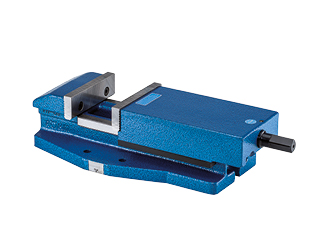

Machine vises for universal use

on milling machines and machining centers up to 100 kN

Machine vises, side mountable

for universal use on milling machines and machining centers up to 50 kN

Machine vises for conventional use

on machine tools up to 55 kN

Drilling machine vises

for handcrafted production and workshops

The F-senso 2

For measurement of clamping force on lathe chucks.