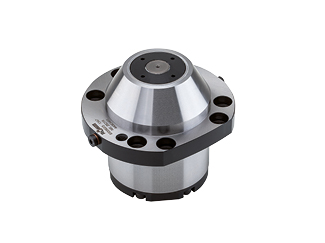

RÖHM clamping heads can be used for all existing pallet clamps. They are particularly suitable for applications which require very high change precision, such as machining centers or transfer lines. Integrated in the machine table, the clamping heads clamp workpiece pallets in a minimum amount of space with high precision in the axial run-out and positioning for maximum efficiency.

The interface consists of two elements: one is the clamping head that is set into the machine table. The other element is the draw-in bolts and mounting flange, which are screwed onto the tool side. The draw-in bolts perform the positive/non-positive connection, and the mounting flange is for centering.

You can find the exact dimensions for your design drawing in our shop.

1: Segmented collet chuck with force-boosting effect for high clamping forces and rigidity

2: Solid centering cone guarantees high loading capacity and accuracy

3: Reliable clamping function due to multi-part spring assembly

4: Hydraulic pistons for releasing the clamping head

Spring operated

for machine tables without hydraulics; sizes: 100 – 140; up to 40 kN

Hydraulic

for machine tables with hydraulics; sizes: 110 – 140; up to 37 kN

Draw-in bolts

for the connection of pallets on the opposite side of the SPK clamping head for the positive/non-positive connection; sizes: 110 – 140; up to 37 kN