Mandrels and collet chucks are used for clamping most rotationally-symmetric workpieces for cutting or grinding machining on machine tools or machining centers. Furthermore, they are used on measuring machines for high-precision clamping. Due to their rather small clamping range, they are used for mainly similar geometries. They can be clamped quickly and above all with a high level of (repeat) accuracy.

Cartridge mandrels, hand-operated

for manual, precision, internal clamping for turning, milling, grinding and gear cutting

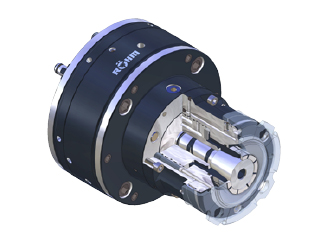

Cartridge mandrels, force-actuated

for automatic, precision, internal clamping for turning, milling, grinding and gear cutting

Cartridge mandrels, classic

for manual internal clamping without end-face stop for measuring operations and easy grinding

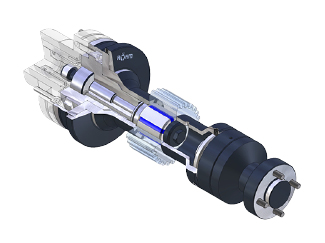

Segment clamping mandrels

for force-actuated, precision, internal clamping for turning, milling, grinding and gear cutting with a quick-change system and long sleeve elongation

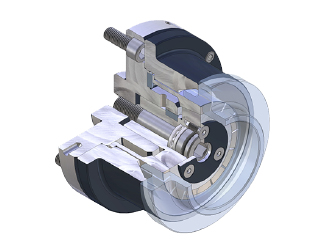

Collet chucks

modular system for precision external clamping for turning, milling and drilling as well as measuring

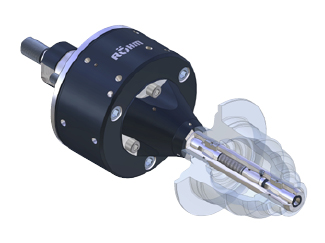

Collet chucks, high-precision

for high-precision, external clamping or workpieces with smooth or toothed outer geometry for turning, milling, grinding and measuring operations

Collet chucks for DIN collets

for external clamping with DIN collets or segment collets for turning, milling and drilling as well as measuring