Drill Chucks

Everything at Röhm started with drill chucks. Röhm has developed and manufactured these practical tool holders for hand-operated and stationary drills for more than 100 years.

Live centers

The live center “with the blue ring” is almost legendary and has become a generic term as the “Röhm center”.

Constant face drivers

A long workpiece that is to be turned over the entire length? Or a sensitive surface that cannot be clamped?

Lathe chucks - Independent chucks

“Sure thing. I turned my first turned parts on a chuck from Röhm eons ago. At that time, it was on a machine that was painted green with a cast iron frame". It feels like that lathe chucks from Röhm have been around forever.

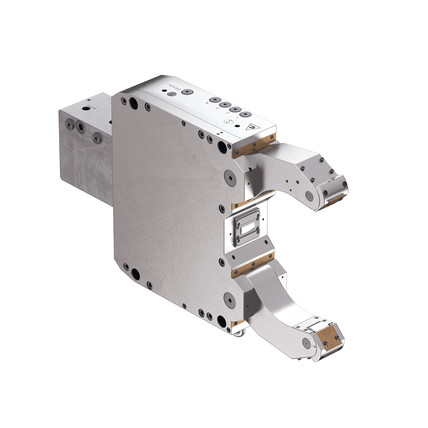

Grippers, Swviel Units

No manufacturing without processing raw parts. For that reason, you know Röhm as a developer of the best clamping technology. But, how does the part get to the machine?

Power Chucks

Power chucks are chucks for cutting and/or grinding machining on machine tools or machining centers.

Steady rests

With the self-centering steady rests, RÖHM makes an important contribution to supporting slender turned parts on turning machines

Mandrels - Collet Chucks

Mandrels and collet chucks are used for clamping most rotationally-symmetric workpieces for cutting or grinding machining on machine tools or machining centers.

Tool clamping systems

SK and HSK are the standardized interfaces for tool changes. Besides the clamping sets, we have a number of complete systems based on them.